RST-H425 Thermoforming Machine of Hard Materials

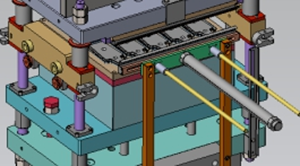

RST-H425 thermoforming machine is characterized by its efficiency, flexibility, and high precision, making it adaptable to various types of plastic materials. It consists of the main body, preheating and forming molds, bottom film feeding mechanism, top film feeding mechanism, modified atmosphere packaging (MAP) sealing system, chain conveyor system, cutting system, waste film recycling system, pneumatic system, cooling system, and control system.

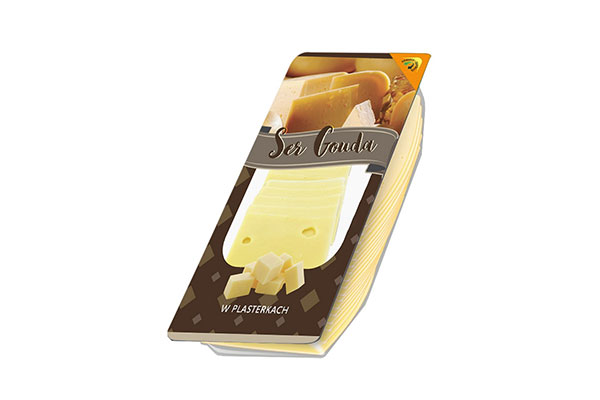

Packaging Effect

RST-H425 Thermoforming Machine Data Sheet

| Model | RST-425H |

| Height of Loading Area (mm) | 950 |

| Length of Loading Area (mm) | 2000 ~ 2500(Extendable) |

| Upper Film Width (mm) | 420~422 |

| Upper Film Outer Diameter(mm) | ≤300 |

| Lower Film Width (mm) | 422~424 |

| Lower Film Outer Diameter(mm) | ≤350 |

| Max. Forming Depth(mm) | 100 |

| Packing Speed(steps/min) | 6~10 |

| Froming Temp(℃) | 90~120 |

| Seling Temp(℃) | 125~160 |

| Power Supply (V/Hz) | 380/50 |

| Water Supply | 0.15~0.45 MPa,Temperature:10~15℃ Clean and free of impurities |

| Air Pressure(MPa) | 0.6~0.8 |

| Total Power (kW) | 18~20 |

| Vacuum Pump Displacement (m³/h) | 200 |

| Dimensions (mm) | 6660x1110x2150 |

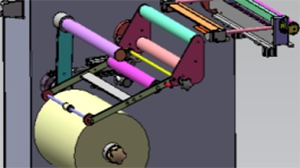

The bottom film system is composed of an active film unwinding structure, a swing-arm tensioning mechanism, and a film position adjustment structure, ensuring precise film feeding and easy film replacement.

The film covering system consists of an active film unwinding structure, a swing-arm tensioning mechanism, a film position adjustment structure, a film brake structure, a cursor detection system, and a cantilever structure, ensuring precise film application.

The highly integrated pneumatic valve seat system features a compact structure that occupies minimal space and facilitates easy maintenance and upkeep.

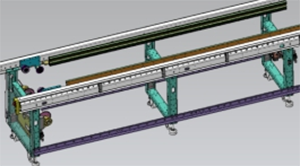

The chain is driven by a servo system, ensuring precise positioning, stable operation, and noiseless performance.

Made from food-grade stainless steel, the machine features a high-strength stainless steel sheet metal structure with excellent stability. The open, modular design minimizes hidden areas where dirt can accumulate, making it easy to clean.

Utilizing EtherCAT bus technology, the system offers UPS power outage data protection, intelligent error diagnostics, operation prompts, temperature and humidity control in the electrical cabinet, and grid monitoring, achieving intelligent production.

The integrated cutting knife features a compact structure and ensures smooth edge cutting.