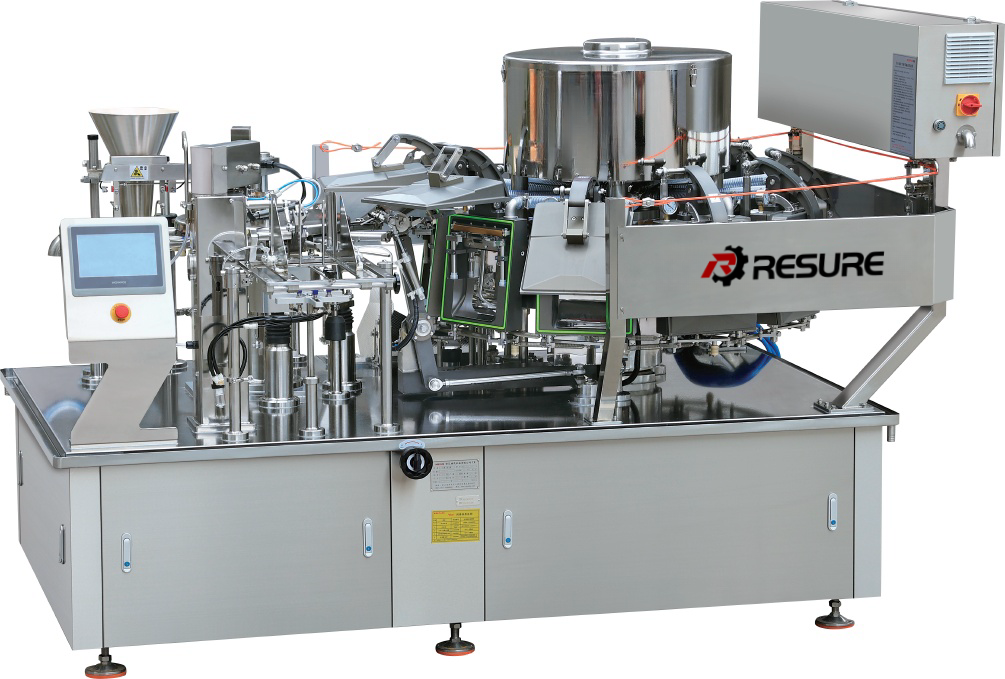

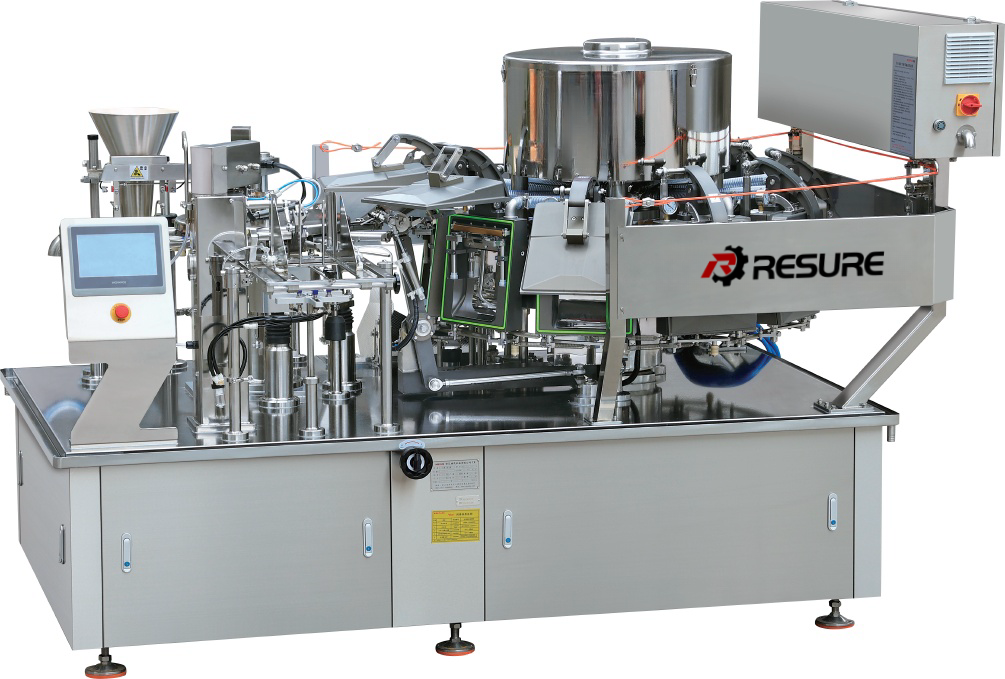

RS8-200E-10ZK Rotary Vacuum Pouch Packaging Machine

The rotary vacuum pouch packaging machine is a high-end packaging solution that integrates automatic pouch feeding, opening, filling, vacuuming, and sealing. It features a rotary structure with multiple stations arranged in a circular layout, where robotic arms collaborate to perform each function efficiently. Known for its fast packaging speed, excellent vacuum performance, and stable operation, this machine is especially suitable for products requiring high freshness and vacuum standards, such as pickled foods, meat products, ready-to-eat foods, and seafood. It is widely used in the food processing industry.

Packaging Effect

Specifications

| Model | RS8-200E-10ZK |

| Pouch Length(mm) | 150~290 |

| Pouch Width(mm) | 120~200 |

| Pouch Thickness(mm) | ≤80 |

| Max.Filling Volume(ml) | ≤1200 |

| Packing Speed(BPM) | ≤55 |

| Total Power(Kw) | 18.52 (Vacuum pump included) |

| Air Consumption(m³/min) | ≥0.4 |

| Weight(kg) | 3000 |

| Dimensions(mm) | 2910×2060×1850 |

Pouch Loading Station

Supports multiple pouch picking methods, including top pick-up, horizontal pick-up, and bottom pick-up, allowing flexible adaptation to different pouch types to meet diverse customer needs.

Pouch Gripping Station

Automatically adjusts the pouch clamp width based on the actual pouch size, ensuring firm grip without manual adjustment. Optional memory function available to save parameters for different products, enabling quick switching via the internal database.

Coding Station

Equipped with a high-quality ribbon coding machine (optional), offering fast-drying and high-speed printing for efficient traceability.

Pouch Opening Station

Suction cups with anti-slip treatment provide strong suction power to ensure pouch opening success. An air-blowing device assists the suction cup for efficient pouch opening. An optional intelligent detection system monitors the bag opening status in real time. If abnormal, the empty pouch is returned to the first station for reloading, minimizing waste and reducing costs.

Filling Station

Customized filling systems tailored to different products, with integrated pouch-support detection to ensure smooth material discharge. The system can intelligently determine the optimal filling timing. If unsuitable, the machine will pause filling and sealing automatically to avoid material loss and reduce costs.

Vacuum Sealing Station

After the pouch enters the vacuum chamber, the pouch mouth is automatically straightened. Equipped with a high-purity copper wire vacuum pump and a chiller, the vacuum sealing is quickly cooled after heating to ensure sealing quality. The system supports independent vacuum chamber control; if a heating system failure occurs in one chamber, it can be shut down individually to prevent sealing defects, ensuring production continuity and improving product yield.

Discharge Station

After sealing, the pouch automatically drops onto a conveyor belt for easy integration with downstream packaging processes.

Additional Features

● Wide packaging range: Suitable for materials of various shapes, states, and properties, such as dried fish, pickled vegetables, and marinated products, meeting diverse packaging needs.

● Easy operation: Controlled by a PLC touchscreen with a user-friendly interface.

● High automation: Fully automatic vacuum process with unmanned operation during weighing and packaging; automatic fault alarms.

● Complies with food machinery hygiene standards: All parts in contact with the product are made of 304 stainless steel or other food-grade materials, ensuring food safety and compliance with GMP standards.

● Waterproof design: The Electrical cabinet is top-mounted for easy cleaning and reduced maintenance effort, extending service life.

● Equipped with a centralized lubrication pump and oil cup system to enhance durability.

● Advanced design ensures stable operation, reduces defect rate, and prolongs machine life.