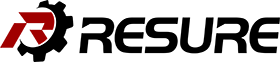

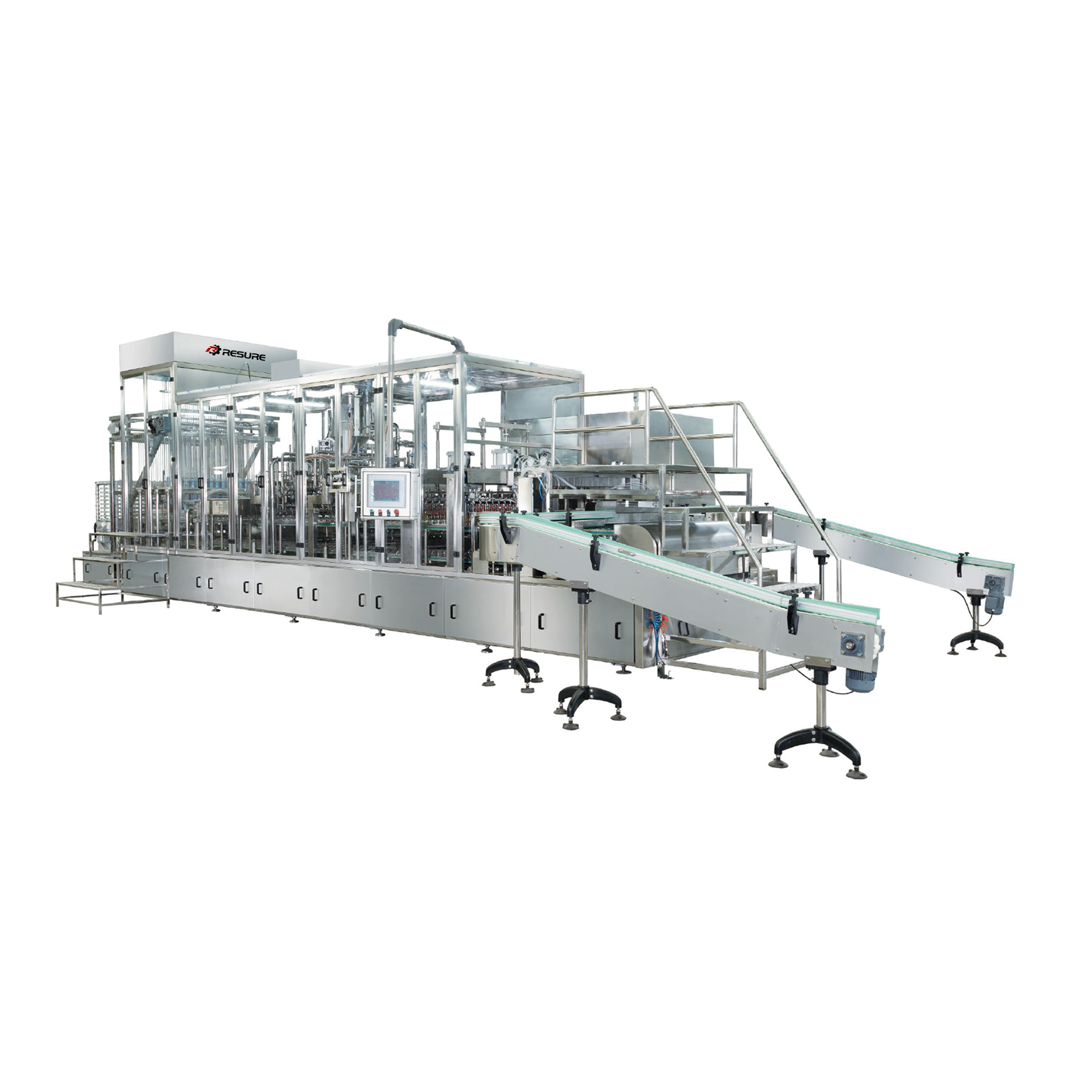

RS-PC Pre-formed Plastic Sealing Machine

This highly efficient packaging system is designed specifically for cup-packaged foods and is suitable for liquid or semi-liquid products such as yogurt, juice, and pudding. The equipment features a clean design, integrating automatic cup transportation, precise filling, single-film sealing, heat sealing, and finished product output, ensuring product hygiene, safety, and sealing integrity.

Packaging Effect

Products Categories

Get A Free Quote

| Model | RS-PC10 | RS-PC12 | RS-PC16 | RS-PC20 | RS-PC24 |

| Volume(mL) | 100~300 | 100~300 | 100~300 | 100~300 | 100~300 |

| Capacity (Cups/h) | 12000~15000 | 14000~18000 | 19000~24000 | 24000~30000 | 30000~35000 |

Technology

- Equipped with a horizontal dual-row cup storage, cup separation, and cup loading system, capable of storing 5,000 cups at once. It can automatically drop cups as needed, reducing manual intervention and improving production efficiency.

- Utilizes a dual-row, four-station rotary film suction and release device, which enhances sealing efficiency while improving the sterilization effect of the sealing film, ensuring food safety.

- Equipped with cup and film sterilization devices to further ensure the hygienic safety of packaging materials during production, complying with food industry standards.

- Adopts a servo-controlled filling device that precisely controls the filling volume, ensuring stable and consistent material filling in each cup, reducing waste.

- Equipped with an on-line mixing and fruit pulp addition device, supporting the uniform addition of fruit pulp, fruit chunks, and other particulate matter during production, ensuring consistent product quality.

- Adopts floating heat sealing technology, which automatically adapts to slight variations in cup rim height, ensuring precise and aesthetically pleasing seals, while enhancing product seal integrity and shelf life.

- Equipped with a bidirectional cup discharge device to optimize the production process.