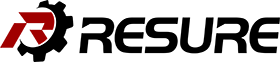

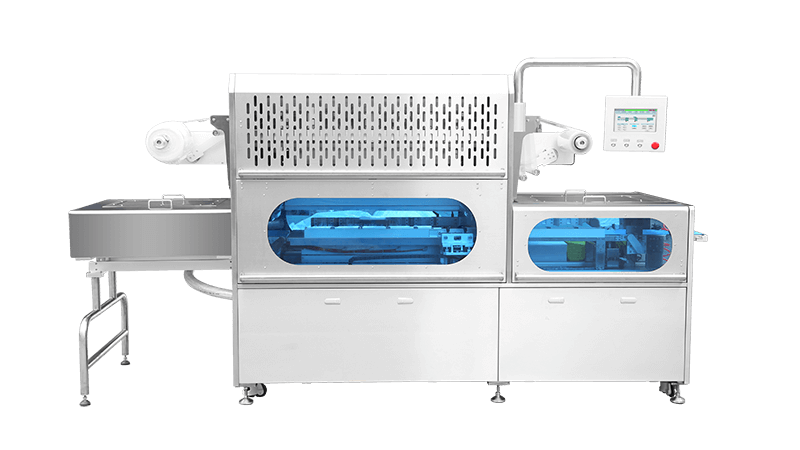

RSC-73V Automatic MAP Tray Sealing Machine

The RSC-73V MAP (Modified Atmosphere Packaging) tray sealing machine is suitable for large-scale production of MAP packaging. It consists of a main body, automatic molds, mixing system, fresh gas replacement system, film feeding mechanism, sealing system, automatic conveying system, and servo control system.

Packaging Effect

Technical Data

| Specifications | |

| Model | RSC-73V |

| Max. Film Width (mm) | 400 |

| Max. Film Diameter (mm) | 260 |

| Gas Mixing Accuracy(%) | ≥99% |

| Single Cycle Time(s) | 6~8 |

| Capacity (trays/hour) output 6 | 2880~3600 |

| Total Power (kW) | 13 |

| Air Pressure (MPa) | 0.6~0.8 |

| Dimensions (mm) | 3920×1120×2000 |

RSC-73V Video

Film Rewinding and Unwinding Mechanism

Dual air shafts with servo control ensure film feeding accuracy within 1mm. The German JSCC motor provides stable, wrinkle-free film feeding. The fully air-operated shaft system allows for easy film changes.

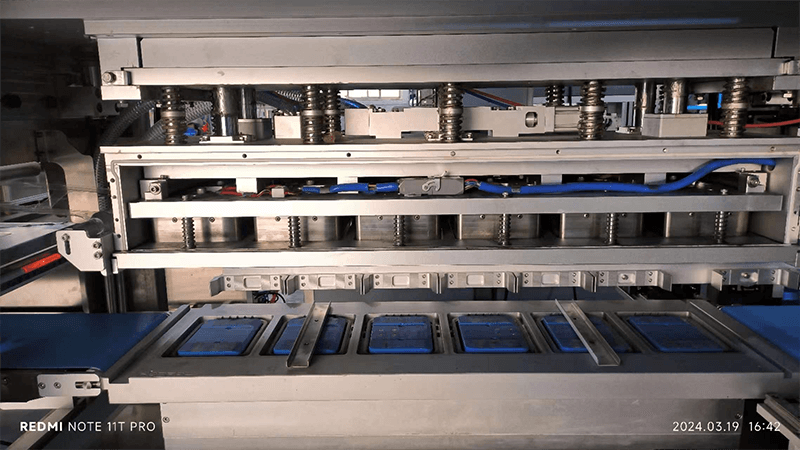

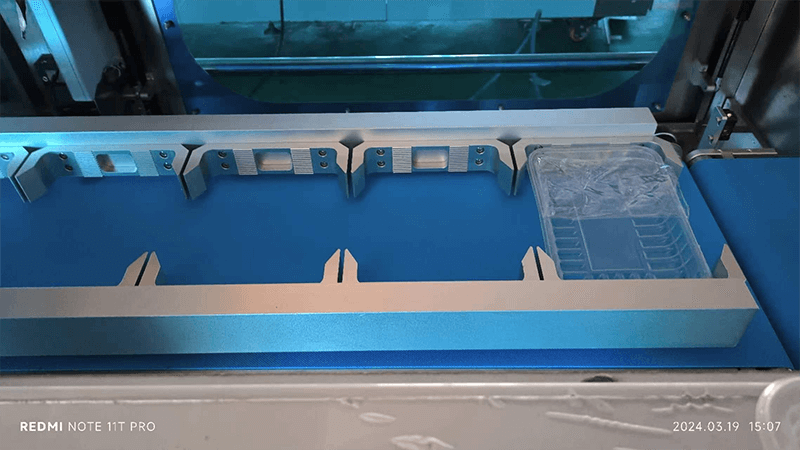

Intelligent Tray Organizing Mechanism

Utilizes smart algorithms for automatic tray sorting and alignment with servo conveyance, requiring no dedicated personnel. Workers simply place trays, and the equipment automatically handles conveying and positioning, enhancing packaging efficiency.

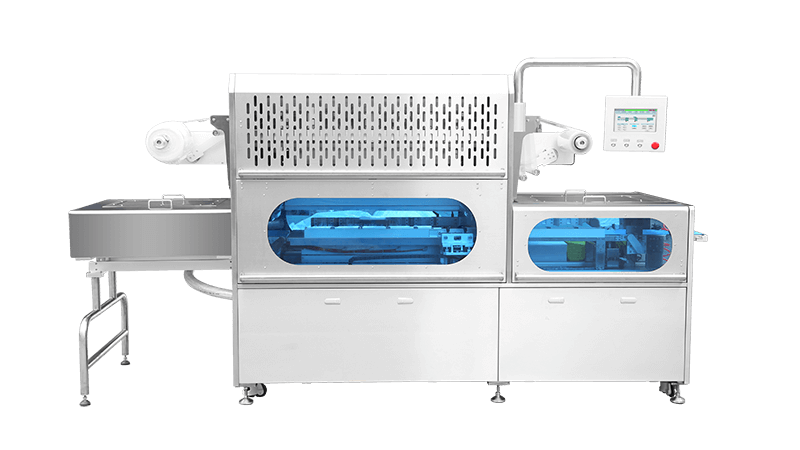

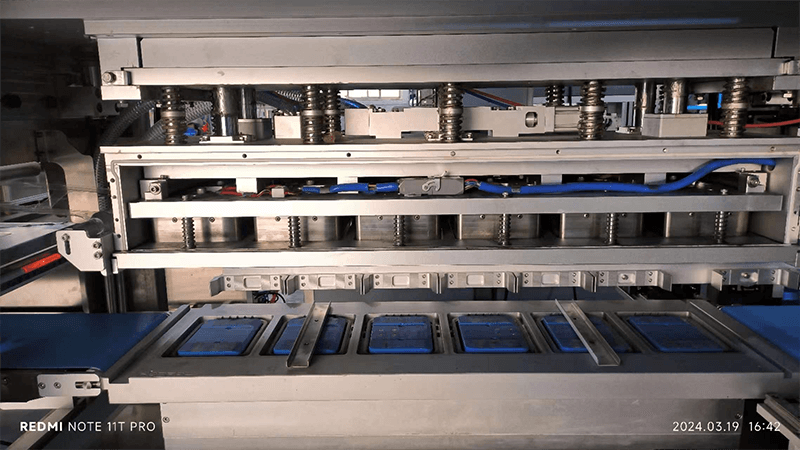

Tray Clamping Conveyor Mechanism

Uses servo control to smoothly and precisely transport trays into molds with high accuracy, preventing tray jamming.

Intelligent Tray Feeding Mechanism

Smartly detects tray misalignment to ensure rapid and accurate placement of trays. Automatically checks if trays are correctly positioned to protect the cutting blade.

Heating System

Features an integrated heating pipe structure for even and efficient heating.

Machine Design

The machine features a 304 stainless steel sheet metal structure, with a gas spring cover for easy cleaning and maintenance.

Technology

- Positive Pressure Replacement System: Utilizes positive pressure gas replacement technology with RESURE patented technology. Ensures stable replacement, with residual oxygen levels in the package below 0.5% and packaging speed twice as fast as similar equipment.

- Low-Pressure Inflation System: Employs a low-pressure inflation system to ensure consistent packaging for each box. The filling pressure is only 0.06 MPa, which saves on preservation gas.

- Internal Cutting and Cutting Blade System (Optional): Features an internal cutting blade with the cut edge on the packaging seal, eliminating edge debris.

Get Free Quote of RSC-73V Automatic MAP Tray Sealing Machine

Related Products

Related News

Packaging Technologies From October 7th to 11th, 2024, Resure made a remarkable appearance at AgroProdMash 2024, held in Moscow. 1. […]